Our unparalleled experience in carrying out work in close proximity to live equipment and on-line plant environments allows us to tailor our working methods to minimize any effects on the day-to-day operations of the client’s facilities. Where required, multi-shift working is adopted to minimize contract durations (for example, to enable removal, maintenance, reinstallation and commissioning to off-line facilities).

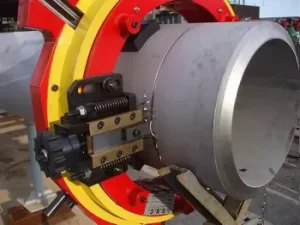

Typical techniques used include unbolting, hot & cold cutting and rigging. In addition to our skilled and trained workforce, the company has a full range of specialized equipment at its disposal. This equipment includes:

- Hydraulic shears

- Wrenches

- Nibblers

- Reciprocating and band saws

- Jacks

- Skates

- Forklift trucks

- Non-sparking tools

- Lifting equipment

- Orbital lathes

- Water jet cutters

All tools and equipment are selected depending upon operational conditions and may be pneumatic, hydraulic, electric, diesel or gas powered. Flameproof tools and equipment are also available for work in potentially flammable atmosphere.